For more than 30 years, dentists have had access to intraoral scanning devices and the ability to manufacture restorations in the dental office. Until recently, intraoral scanners‘ primary function was to scan a single tooth or a small group of teeth in order to design and manufacture same-day restorations. The usage of intraoral scanners were only creating “digital impressions” . And the digital files that came with them were rarely used for anything else.

Using Intraoral Scanning for Enhancing Patient Education

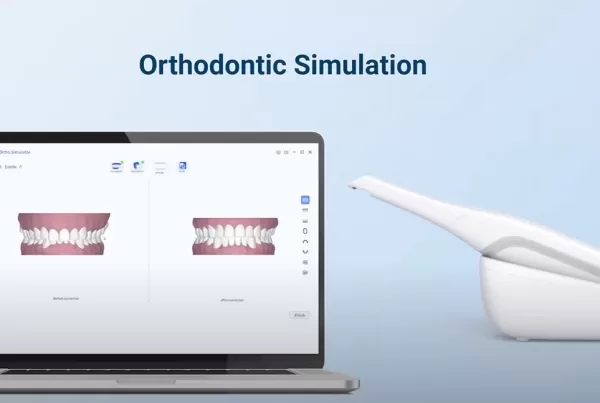

However, things have changed a lot these days. Many practices is now using intraoral scanning for more than just manufacturing. It is used during all new patient visits as well as annual recalls. An important aspect of a patient’s first visit is an intraoral scan. They are also educational tools to explain findings, engage patients, and create a one-of-a-kind patient experience. By live-streaming the intraoral scan, the patient can take part in the scanning procedure. As a result, patients can interact visually with their dental findings, creating a powerful communication tool for the provider.

Using Intraoral Scanning for Updating Diagnosis, and Treatment

Furthermore, clinicians can now digitally export the scanned data to a dental laboratory of their choice for processing and fabrication of the restorations without the restriction of specific hardware and software. They can also use their digital scans for in-house manufacturing. This leads to the CAD/CAM dentistry in the dental clinics, which is also known as digital chairside dentistry. All CAD/CAM systems consist of a computer aided design (CAD) and computer aided manufacture (CAM) stage. And the key stages can broadly be summarized as the following:

- Optical scanning that captures the intraoral condition of the patient.

- Use of software that can turn the captured images into a digital model. So we can design and prepare for dental prosthesis fabricationa.

- Instruction to devices that can facilitate the conversion of the design into a product by way of 3D printing of milling depending on the CAD/CAM system.

CAD/CAM has improved the quality of dental prostheses and standardized the manufacturing process. It has increased productivity and accuracy. The use of intraoral scanning is becoming an indispensable part of this, which enhances the treatment experience for both patients and dentists.

Nowadays, intraoral scanning is becoming an essential component not only in patient diagnosis and treatment planning, but also in patient education and long-term management. This brings a lot of benefits for both the patient and the clinic, such as higher trust and better communication. It is also a good time for you now to bring intraoral scanning into your clinic with BLZ Dental. This will update your patients’ treatment experience, as well as your work efficiency.

Reference:

[1] Diagnostic Intraoral Scanning: Technology Enhances Patient Education, Diagnosis, and Treatment