In a very short period of time, the model-less workflow has revolutionized dental fabrication. A model-less workflow with intraoral scanner has obvious advantages of the fabrication process at nearly every stage. From digital impressions to final fit, a model-less workflow is often faster, more accurate, and requires less adjustment to achieve the perfect result.

Faster

A right intraoral scanner can significantly shorten the time it takes to complete a treatment for your patients. You no longer have to deal with impressions and molding materials. This eliminates the need for your patients to spend time sitting in a chair waiting for a mold to set, and tasting the unpleasant impressions material.

The model-less process also reduces design and review time significantly. Traditional model-based procedures frequently require you to wait two or more weeks for your lab to complete the restoration item before beginning the fitting process. A model-less process, on the other hand, can easily produce a final product within 48 hours, and even within 24 hours in the most time-sensitive cases.

Better Production Quality

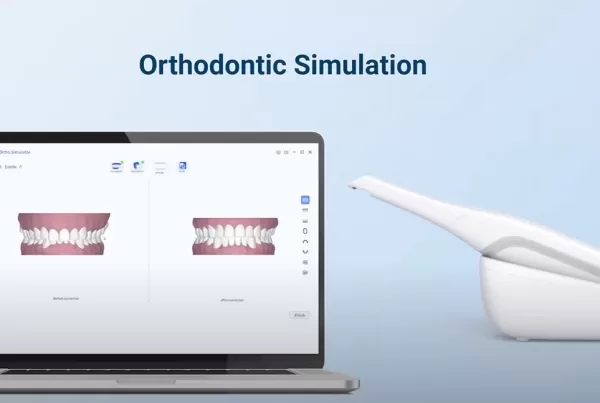

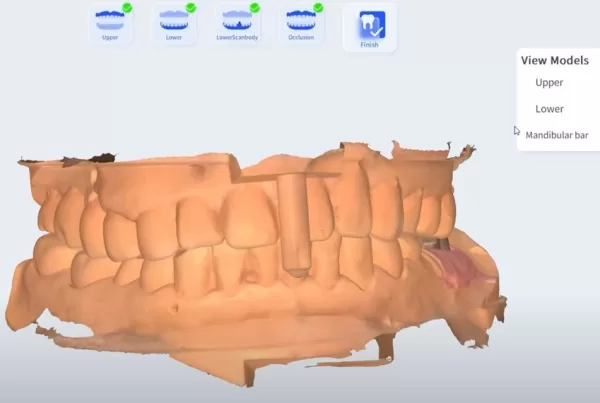

If there is one thing about intraoral scanning that matters most, it must be the accuracy of obtaining the models. The errors are reduced to the greatest extent, because there are no inconveniences such as bubbles, setting, wrinkles or cracks during the process of taking impressions. You will no longer have to deal with distortions and model inaccuracies, and any errors in the scan will be immediately identified and fixed.

Better Cost Efficiency

When you switch to a model-less workflow, you can get rid of all of the supplies and equipment needed for a purely impressions-based fabrication process. This means that the initial investment in digital scanning equipment may pay for itself quickly, and you will no longer need to order and track as much inventory for your impressions-based procedures.

Better Communication

Because digital scanning processes provide immediate feedback, you can begin communicating with your physicians as soon as you finish scanning. This faster communication dynamic is carried over into the fabrication process, where your lab can easily notify your office of any issues, allowing for real-time consultations to adjust the final result as needed and ensure a good fit for your patients.

Conclusion

In general, model-less workflow has grown in popularity alongside the tide of dental digitalization. This is an unavoidable trend brought about by the global environment of internalization and digitalization. This transition can benefit both dental clinics and patients. So, let us learn and begin the exciting task of bringing your dental clinics into the new digital dentistry era with the INO100 intraoral scanner!

Reference:

https://www.dentalproductsreport.com/view/top-6-benefits-digital-impressions-and-model-less-workflow